A few months ago, lithium shortage seemed a burning issue: facing insufficient mining resources was insatiable demand for electric vehicles. And commentators were ignited by the potential for geopolitical conflict over these « rare metals »; probably a little too fast.

Lithium production comes from two sources, which were approximately equivalent in each year: the first in dissolved form from the « salars », the brines of the salt deserts of the Chilean, Argentinean and Bolivian mountains, or even Tibet; the second in solid form, the « spodumens », minerals containing lithium extracted from mines, particularly Australian mines.

To meet the huge consumption of batteries for electric cars that is coming, the solution seemed to come initially from an increase in the production of salars, especially Chilean ones. But this perspective has proved insufficient. Following the accusation of production quota overruns by the two leading companies, SQM and Albermare, the renegotiation with the Chilean supervisory ministry was not fully successful: the conflict concerns the royalties to be paid to the State, production concessions and their environmental impact.

Australian breakthrough

As a result, Australia has made the breakthrough since 2016: thanks to a considerable increase in its mining production of spodumene, it has become the world’s leading producer ahead of Chile. They are followed by China with its deposits in Tibet and Qinghai, and then come other producers, or will be including Serbia, where the Jadar mine project has been confirmed.

In addition to the development of Australian mines, an attempt has been made to improve the quality of Andean salt production. Traditionally operating by evaporation, their production cycle, depending on the weather, lasted between 12 and 18 months, or in some cases several years.

Other drawback, the ratio between the lithium recovered and the lithium remaining in salars was usually only 50%. Now, although there are still costs to be improved and processes to be tested, hydrometallurgy can extract 80% to 90% of lithium in a few hours. The multiplier effect is doubly important: fewer resources and surface area producing more and faster the environmental impact will be less, and the recycling loop will be accelerated.

Market reversal

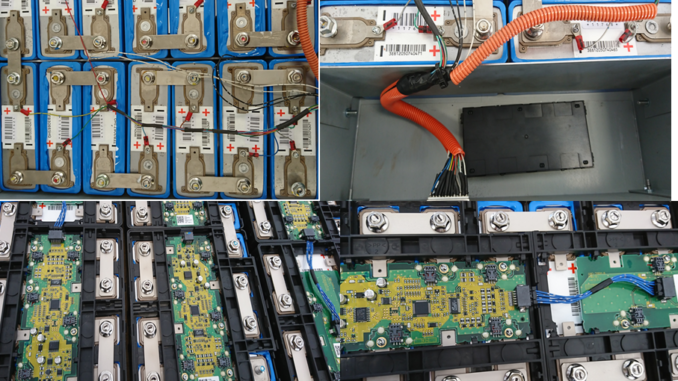

Finally, on the demand side, lithium batteries are constantly evolving, leaving behind them two sectors with very different profitability levels.

On the one hand, lithium-iron phosphate batteries, the oldest and least expensive, are used in low-end electric vehicles, i.e. with a low mileage range. This technology embeds lithium carbonate in the direct production of salars.

On the other hand, lithium nickel-manganese cobalt (NMC) batteries are used in high-end vehicles that require long range and to go fast. They consume lithin or lithium hydroxide, produced from the carbonate of Andean salars or directly from spodumene mines.

It would be tempting to say that salars will produce lithium carbonate for small vehicles, and spodumenes for heavier ones. But one novelty brings another, lithium hydroxide, generally more expensive than carbonate, can be produced more economically from Australian spodumens than through the Andean carbonate stage. A further cost reduction, in addition to the reduction in lithium prices already cut threefold since the spring 2016 peak, would be excellent news for NMC batteries.

It could even become competitive to produce carbonate from Australian lithine instead of obtaining it directly from the Andean triangle. Such a market reversal would condemn the production of salars to follow the production costs of Australian mines downwards, whereas until recently, it was in Santiago hands to made world prices. In the long term, the progress of production technologies will undoubtedly lead to a new economic equipollence between the two sources of carbonate and lithine.

Lower prices and competition

A few months ago, the imbalance between supply and demand justified questions. But with the exploitation of new fields, consumers have regained a relative peace of mind since doubling or even tripling current production to reach one million tonnes per year is being considered more calmly.

However, the increase in capacity would lead to lower prices and increased competition between producers on both sides of the Pacific. If this competition continues without progress in refining techniques and process flexibility, or without the increase in the penetration rate of electric cars generating a slight price increase, then new lithium production projects, particularly in South America, could be postponed.

The lithium war has therefore not taken place, and perhaps never will if, following the NMC batteries, and after the next stage of solid lithium batteries (without nickel-manganese cobalt alloy), lithium disappears as well and is replaced by an abundant element, such as sodium.